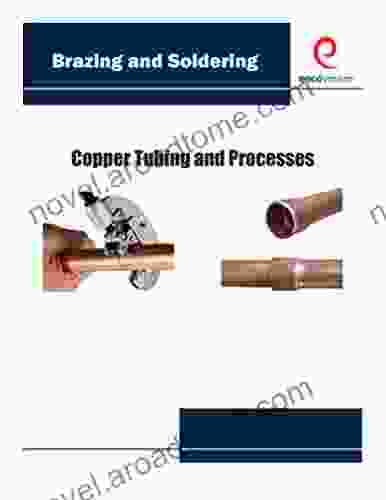

Brazing, Soldering, Copper Tubing, and Processes: The Ultimate Guide

5 out of 5

| Language | : | English |

| File size | : | 2507 KB |

| Screen Reader | : | Supported |

| Print length | : | 246 pages |

If you work with metal, then you've probably had to braze or solder at some point. These two techniques are essential for joining metal together, and they're used in a wide variety of applications, from plumbing and HVAC to automotive repair and jewelry making.

In this guide, we'll cover everything you need to know about brazing and soldering, including:

- The difference between brazing and soldering

- The different types of brazing and soldering alloys

- The equipment you need for brazing and soldering

- The step-by-step process for brazing and soldering

- Troubleshooting tips for brazing and soldering

The Difference Between Brazing and Soldering

Brazing and soldering are both metal-joining techniques that use a molten metal to create a bond between two pieces of metal. However, there are some key differences between the two processes.

The most important difference is the temperature at which the two processes are performed. Brazing is performed at a higher temperature than soldering, typically between 1,100 and 1,800 degrees Fahrenheit. Soldering, on the other hand, is performed at a lower temperature, typically between 450 and 700 degrees Fahrenheit.

Another difference between brazing and soldering is the type of metal that is used. Brazing alloys are typically made of copper and zinc, while soldering alloys are typically made of tin and lead. Brazing alloys have a higher melting point than soldering alloys, which is why brazing is performed at a higher temperature.

Finally, brazing and soldering differ in the strength of the bond that they create. Brazed joints are typically stronger than soldered joints, which is why brazing is often used for applications where strength is important.

The Different Types of Brazing and Soldering Alloys

There are many different types of brazing and soldering alloys available, each with its own unique properties. The type of alloy that you choose will depend on the specific application that you are working on.

Some of the most common brazing alloys include:

- Copper-zinc alloys

- Copper-silver alloys

- Copper-phosphorus alloys

- Copper-aluminum alloys

- Nickel-based alloys

Some of the most common soldering alloys include:

- Tin-lead alloys

- Tin-antimony alloys

- Tin-silver alloys

- Tin-zinc alloys

- Lead-free alloys

The Equipment You Need for Brazing and Soldering

The equipment that you need for brazing and soldering will vary depending on the specific process that you are using. However, there are some basic tools that you will need for both processes. These tools include:

- A heat source

- A flux

- Brazing or soldering alloy

- Safety glasses

- Gloves

In addition to these basic tools, you may also need some specialized equipment for specific applications. For example, if you are brazing copper tubing, you will need a torch and a flux that is specifically designed for copper.

The Step-by-Step Process for Brazing and Soldering

The step-by-step process for brazing and soldering is similar for both processes. The following steps will guide you through the general process:

- Clean the metal surfaces that you will be joining.

- Apply a flux to the metal surfaces.

- Heat the metal surfaces until they reach the appropriate temperature.

- Apply the brazing or soldering alloy to the joint.

- Allow the joint to cool and solidify.

Troubleshooting Tips for Brazing and Soldering

If you are having trouble brazing or soldering, there are a few things that you can check:

- Make sure that the metal surfaces are clean and free of any dirt or grease.

- Make sure that you are using the correct flux for the metal that you are working with.

- Make sure that you are heating the metal surfaces to the correct temperature.

- Make sure that you are applying the brazing or soldering alloy to the joint correctly.

If you are still having trouble, you may want to consult with a professional.

Brazing and soldering are essential metal-joining techniques that are used in a wide variety of applications. By understanding the difference between the two processes, choosing the right alloy, and following the proper steps, you can successfully braze and solder metal.

5 out of 5

| Language | : | English |

| File size | : | 2507 KB |

| Screen Reader | : | Supported |

| Print length | : | 246 pages |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Book

Book Novel

Novel Page

Page Chapter

Chapter Text

Text Story

Story Genre

Genre Reader

Reader Library

Library Paperback

Paperback E-book

E-book Magazine

Magazine Newspaper

Newspaper Paragraph

Paragraph Sentence

Sentence Bookmark

Bookmark Shelf

Shelf Glossary

Glossary Bibliography

Bibliography Foreword

Foreword Preface

Preface Synopsis

Synopsis Annotation

Annotation Footnote

Footnote Manuscript

Manuscript Scroll

Scroll Codex

Codex Tome

Tome Bestseller

Bestseller Classics

Classics Library card

Library card Narrative

Narrative Biography

Biography Autobiography

Autobiography Memoir

Memoir Reference

Reference Encyclopedia

Encyclopedia Svetla Bankova

Svetla Bankova Sundari Venkatraman

Sundari Venkatraman Sam W Wiesel

Sam W Wiesel Rebecca Dolton

Rebecca Dolton Tabakmann

Tabakmann Robert O Young

Robert O Young Romesh Ranganathan

Romesh Ranganathan Yelena Mackay

Yelena Mackay Swiyyah Butler

Swiyyah Butler Sarah Chauncey

Sarah Chauncey Rebecca Keating

Rebecca Keating Ricky Monahan Brown

Ricky Monahan Brown Revathi Kesavamani

Revathi Kesavamani Sandra Michaelson

Sandra Michaelson S E Clancy

S E Clancy William Archer

William Archer Robert C Brears

Robert C Brears Stephen Wing Kai Chiu

Stephen Wing Kai Chiu Thearon Willis

Thearon Willis Robert Thiel

Robert Thiel

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Jesus MitchellLearn 000 Basic Korean Words And Phrases Quickly And Easily Hangul Romanized

Jesus MitchellLearn 000 Basic Korean Words And Phrases Quickly And Easily Hangul Romanized

Boris PasternakDiscover the Unforgettable Story of Courage and Resilience in "The Seamstress...

Boris PasternakDiscover the Unforgettable Story of Courage and Resilience in "The Seamstress...

Terence NelsonAnd Other Tales of Drunken Debauchery: A Litany of Inebriated Escapades and...

Terence NelsonAnd Other Tales of Drunken Debauchery: A Litany of Inebriated Escapades and... August HayesFollow ·12.5k

August HayesFollow ·12.5k John GrishamFollow ·18.9k

John GrishamFollow ·18.9k Alvin BellFollow ·16.5k

Alvin BellFollow ·16.5k Hayden MitchellFollow ·10.3k

Hayden MitchellFollow ·10.3k Duane KellyFollow ·15.1k

Duane KellyFollow ·15.1k Orson Scott CardFollow ·15.9k

Orson Scott CardFollow ·15.9k Bryan GrayFollow ·14.2k

Bryan GrayFollow ·14.2k Oscar WildeFollow ·13k

Oscar WildeFollow ·13k

Eli Brooks

Eli BrooksOver 700 Organic Remedies Shortcuts And Tips For The...

: Embracing the Power of...

Carter Hayes

Carter HayesUnveiling the Unofficial Political Religion of India: A...

Embark on an...

Colin Richardson

Colin RichardsonOf Colors and Critters: A Journey Through the Animal...

In the tapestry of...

Harry Hayes

Harry HayesUnveiling the Hidden Truths: Mao, Stalin, and the Korean...

Step into the enigmatic realm of the 20th...

George Bernard Shaw

George Bernard ShawBand 1b Pink: A Journey Through the World of Reading

Band 1b Pink is a...

5 out of 5

| Language | : | English |

| File size | : | 2507 KB |

| Screen Reader | : | Supported |

| Print length | : | 246 pages |